When it comes to the smooth operation of industrial machinery, shaft alignment is crucial. Misalignment can lead to costly breakdowns, increased wear and tear, and reduced operational efficiency. This is where **ShaftStop** comes into play. If you’ve encountered persistent issues with shaft misalignment, or if you’re looking to optimize your equipment’s performance, ShaftStop offers a comprehensive solution to address these concerns.

What is ShaftStop and How Does It Work?

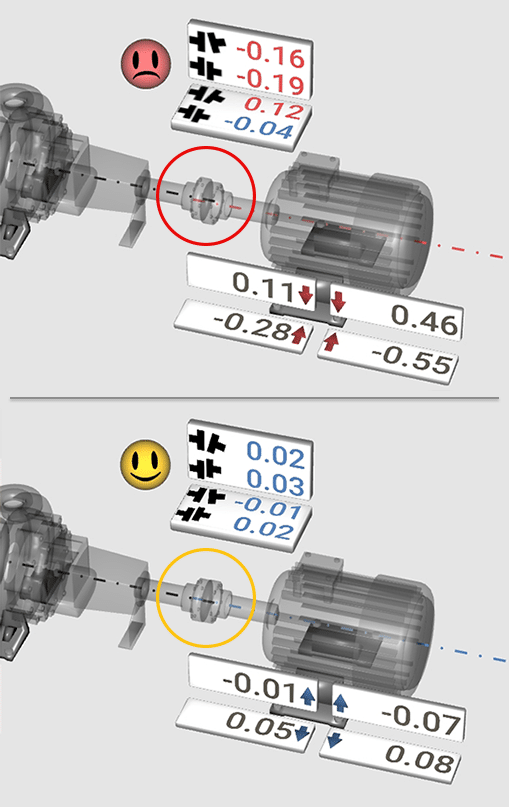

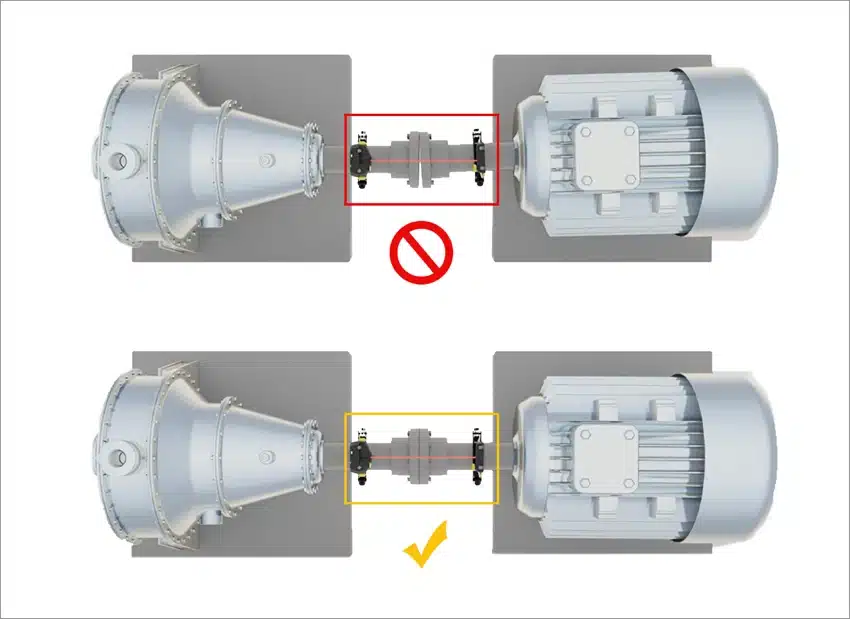

ShaftStop is a revolutionary technology designed to address shaft misalignment issues in various types of machinery. Misalignment occurs when the rotating shafts of connected machinery components are not properly aligned, leading to excessive vibration, energy loss, and premature part failure. ShaftStop provides an effective solution by offering a tool or system that corrects misalignment quickly, efficiently, and with minimal downtime.

Using advanced sensors and mechanical components, ShaftStop automatically detects misalignment and takes corrective action. The device adjusts the positioning of shafts, aligning them with precision, ensuring that machines run smoothly. This technology is used widely in industries such as manufacturing, oil and gas, mining, and any other sector that relies on heavy machinery.

Benefits of ShaftStop in Preventing Downtime

One of the most significant benefits of ShaftStop is its ability to minimize downtime. In any industry, downtime equates to lost production, which directly impacts the bottom line. Traditional shaft alignment methods can be time-consuming, often requiring manual adjustments and lengthy procedures. However, ShaftStop streamlines this process, offering real-time alignment corrections that keep your equipment running without unnecessary delays.

With ShaftStop in place, you not only prevent costly repairs but also enhance the overall lifespan of your machinery. By regularly using ShaftStop to ensure proper alignment, you reduce the chances of severe wear, which in turn reduces maintenance costs and extends the life of critical components.

Common Signs That Your Machinery May Need ShaftStop

Recognizing the early signs of shaft misalignment can prevent more severe damage and costly repairs. Here are a few common indicators that your machinery may need ShaftStop:

– **Vibration**: Excessive vibration is often the first sign that something is wrong with your equipment. Misaligned shafts can cause uneven distribution of power, leading to vibrations that worsen over time.

– **Increased Heat**: Misalignment can lead to friction between moving parts, generating unnecessary heat. If you notice unusually high temperatures around your machinery, it could be a result of misalignment.

– **Noise**: Strange, grinding, or squealing noises are often heard when machinery isn’t properly aligned. These sounds indicate that the components are rubbing against each other more than they should.

– **Accelerated Wear**: Misalignment increases the load on certain parts, causing them to wear out faster. If your components are wearing down prematurely, shaft misalignment could be the culprit.

By using ShaftStop to detect and address these issues promptly, you can save both time and money while keeping your operations running smoothly.

ShaftStop in Action: Real-Life Applications

ShaftStop has been successfully integrated into various industries, offering remarkable results. For example, in the manufacturing sector, a large production facility was experiencing constant downtime due to shaft misalignment in its conveyor systems. After installing ShaftStop, the facility was able to eliminate the misalignment issues, reduce vibration, and increase throughput by 20%.

In the mining industry, where machinery operates under extreme conditions, ShaftStop has proved invaluable in maintaining operational efficiency. Misalignment in mining equipment can lead to catastrophic failures. By implementing ShaftStop, many mines have seen significant improvements in the reliability and longevity of their heavy-duty machinery.

Conclusion: Why ShaftStop is Essential for Your Machinery

Whether you’re dealing with high-speed machines, heavy-duty equipment, or industrial machinery, ShaftStop offers a smart, efficient solution to ensure that your shafts remain properly aligned. By addressing misalignment before it leads to costly damage, ShaftStop not only saves you money but also enhances the overall performance and longevity of your equipment.

Investing in ShaftStop is more than just a repair tool—it’s an essential part of any maintenance strategy, improving productivity and minimizing the risk of unexpected breakdowns. So, if you’re ready to take control of your machinery’s alignment and boost its efficiency, it’s time to consider the power of ShaftStop.

By incorporating ShaftStop into your operations, you can ensure that your machines are always in top shape, avoiding costly downtime and extending the life of your valuable equipment.

—

**Keywords:** ShaftStop, shaft misalignment, machinery maintenance, downtime prevention, equipment efficiency, vibration reduction, machinery lifespan, industrial machinery